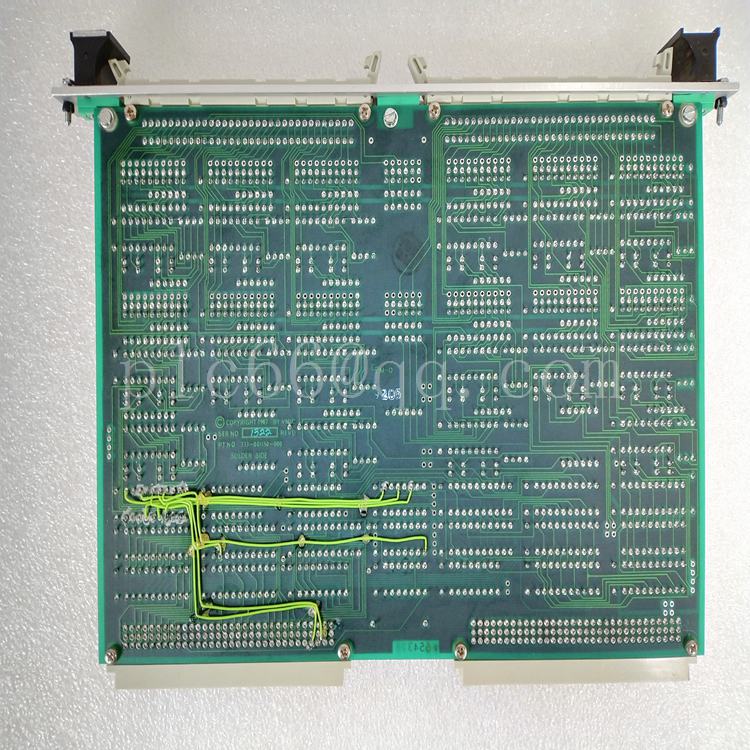

DS200CDBAG1A contactor driver board

DS200CDBAG1A contactor driver board

Consider that the GE Contactor Driver Board DS200CDBAG1A is regularly modified to improve the device's components, reliability, and operation.However, compatibility between all revisions is guaranteed.For example, you can buy the latest version of a development board and install it on your drive, and it will be compatible with the older version you deleted.If the circuit board needs to be replaced, installation is quick and easy.This is due to the driver's design allowing easy access to the circuit board.For safety reasons and to protect all components, you must remove power from the drive.Wait a few minutes to remove all power.Then test any circuits to make sure all power is disconnected before touching them with your hands.Open the cabinet door of the drive where the damaged board is located.You may find that there are multiple wires connected to the damaged circuit board.Before you remove them, label any unlabeled ones to make installation easier.Connector 1TB has a 2 part connector.Use a screwdriver to

Product introduction: Model: DS200CDBAG1A Performance and features: 1. The transmission interface of the planetary gear adopts a full-needle needle roller bearing without a cage, which increases the contact area to improve structural rigidity and output torque; 2. Using 3D/PORE design analysis technology, The tooth shape and lead of the spiral tooth surface are modified respectively to reduce the impact and noise of the gear meshing in and out, and increase the service life of the gear system; 3. The gear material is made of high-grade chromium-molybdenum-vanadium alloy steel, which has been quenched and tempered. Heat treatment until the base material hardness is 30HRC, and then use the factory's advanced ion nitriding equipment to nitride the hardness of the gear surface to 840HV to obtain the best wear resistance and impact resistance toughness; 4. The planetary arm frame and the output shaft are integrated Structural design, and the bearing configuration of the output shaft adopts a large-span desig